The Belt Thickener is designed for low polymer consumption high throughput rates and high solids content and is available in six standard sizes. But Did You Check eBay.

Sludge Treatment Gravity Belt Thickening Sludge Processing

A mix of primary or secondary sludge can easily be thickened to 7 wt pure secondary to over 5.

. Advantages and disadvantages of gravity thickening. Design calculations to determine the required thickener area the most important design parameter and ultimately the maximum steady state underflow concentration that is possible for a given solids throughput. The Gravabelt delivers pumpable thickened sludge.

PowerDrain belt thickener a very efficient technology for thickening prior to dewatering. Knock-out panel equipment removal. Presently the area requirements of secondary clarifiers are based on a surface loading rate of approximately 800 galft2day.

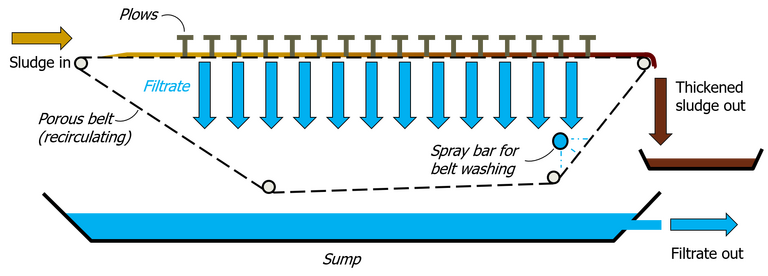

Full width weir for smooth transition to the belt utilizing the complete area of the gravity deck. Gravity thickening is the process by which biosolids are condensed to produce a concentrated solids product and a relatively solids-free supernatant. A common variant on the gravity thickener design is the picket fence thickener.

The biosolids technology fact sheet for gravity thickening provides. Gravity Thickener Design Example. The volume reduction obtained by sludge concentration is beneficial to subsequent treatment processes such as digestion dewatering drying and combustion from the.

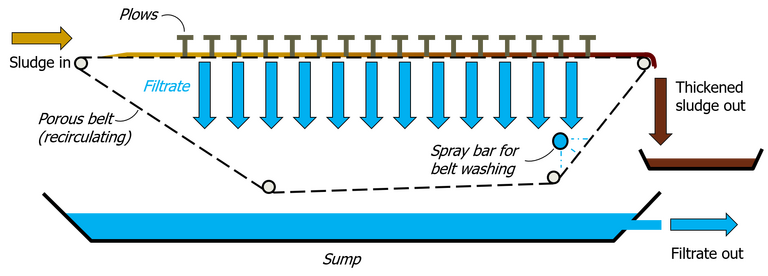

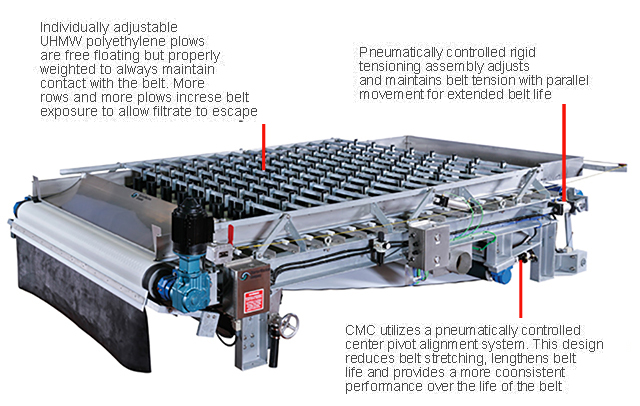

Low energy consumption. GRAVITY BELT THICKENER The OMEGA Gravity Belt Thickener is designed for continuous mechanical thickening of municipal or industrial sludge. Reliable and durable components.

Specially designed ploughs as well as the very large open area under the belt optimize the draining effect. A spreader plate ensures uniform distribution over the working width of the belt. Built on top of existing tank Cast-in-place concrete floor slab Sealed from tank below to prevent tank atmosphere into building Insulated concrete block walls.

The sl udge thickener works on the principle of separating liquid from solids by gravity drainage through a slowly rolling belt cloth. Application The Alfa Laval AS-H Belt Thickener is a gravity belt thickener used to thicken dilute sludge and slurries particularly those from biological and activated sludge processes. In addition the capital cost ofa thickener will be dependent on the calculated required settling area.

This technology is fitted with a stirrer comprising a series of relatively closely-spaced vertical arms and is therefore similar in appearance to a picket fence. The design provides for low maintenance costs and long operational life in the highly corrosive environment of sludge thickening. This sludge continuously enters the thickener and the thickened sludge is continuously withdrawn at a concentration of 21 gml 1302 lbft3.

Gravity Belt Thickener Problem. It is suitable for all municipal sludge types and. The PowerDrain gravity belt thickener is a highly efficient and economical solution for sludge thickening.

Besides reducing subsequent chemical and volumetric require- ments in dewatering processes gravity thickening is also an important consideration in the design of secondary clarifiers. You must think this Web site has an affiliate partnership andor another content link on the individuals or enterprises pointed out in or linked to from this page and should get commissions from purchases you make on subsequent Sites. A mix of primary or secondary sludge can easily be thickened to 7 wt pure secondary to over 5.

Check Out Gravity Belt Thickener On eBay. New Plow Design The Gravity Belt Thickener is used to thicken sludge prior to centrifuge or digestion processes. Gravity belt thickener design Content CONNECTION DISCLOSURE.

The thickener design based on the solids flux data obtained in the Iaboratory involves the. Upflow design constructed of 304 or 316 stainless steel. New Plow Design The Gravity Belt Thickener is used to thicken sludge prior to centrifuge or digestion processes.

After the sludge is flocculated in the feeding pipe it enters the gravity zone where most of the liquids and solids are separated. The simple rugged design offers a number of benefits. It uses a sludge polymer mixing valve with an adjustable lever arm to ensure sufficient turbulent sludgepolymer mixing.

OMEGAs innovative and efficient technology reduces sludge volume by at least 4 times. Ad Free Shipping Available On Many Items. Ad Industrial Filtration System Parts Filters And Services For Any Application.

Flotation centrifugation gravity belt and rotary drum 1. For both designs the sludge enters the centre of a cylindrical tank and flows out to the periphery. Komline-Sandersons Gravabeltgravity belt thickener is designed to obtain high volume reduction and high hydraulic throughput at a low polymer dose.

Applicability to wastewater treatment plants. Gravity thickener designs usually include circular tanks 3-4 m 10-13 ft deep and up to 25 m 82 ft in diameter. A description of gravity thickening.

ANDRITZ PowerDrain gravity belt thickener for efficient sludge treatment. 2m Belt Frequent Cleaning Removal and reinstall 2 year life Feed Rate not at design. High unit capacity per floor space Low residence time eliminates septicity and float scum Superior thickening.

Gravity Belt Thickener Design. The dimensions are based on prediction of settling due to gravity alone. Gravity Belt Thickening to Increase Efficiency City of Elyria Wastewater Pollution Control Plant.

To assist solids transport gravity thickener bottoms are constructed with a floor slope between 16 and 13. Polymer is injected through four tangential inlets in the injection ring upstream of the stainless steel venturi and counterweighted orifice plate. High unit capacity per floor space Low residence time eliminates septicity and float scum Superior thickening.

Gravity Belt Thickener GBT Andritz. For the purposes of this example the solids to be thickened are excess activated sludge with an initial solids concentration of 7 gml 0434 lbft3.

Gravity Belt Thickener Belt Filter Press Sludge Dewatering Charter Machine Company

Andritz Separation Powerdrain Gravity Belt Thickener Youtube

14 Schematic Of A Combined Gravity Belt Thickener And Dewatering Unit Download Scientific Diagram

Gravity Belt Thickening Equipment To Thicken Primary Or Secondary Sludge By Bdp Industries

Gravity Belt Thickening Equipment To Thicken Primary Or Secondary Sludge By Bdp Industries

0 comments

Post a Comment